Revision History

|

Rev. |

Description of Modification |

Date |

|

0 |

First Issue for Comments |

10 August 2021 |

Revision History

|

Rev. |

Description of Modification |

Date |

|

0 |

First Issue for Comments |

10 August 2021 |

CONTENTS

6. Summary of Monitoring Exceedance, Complaints, Notification of Summons and Prosecutions

9. Conclusions and Recommendations

|

Appendix A |

|

|

|

|

|

Appendix B |

Summary of Implementation Status of Environmental Mitigation |

|

|

|

|

Appendix C |

Impact Monitoring Schedule of this and next Reporting Period |

|

|

|

|

Appendix D |

|

|

|

|

|

Appendix E |

|

|

|

|

|

Appendix F |

|

|

|

|

|

Appendix G |

|

|

|

|

|

Appendix H |

|

|

|

|

|

Works Description |

Location |

|

· Installation of pipe piles at Lookout Point · Marine predrilling works at Breakwater Area. · Installation of pipe piles at Landing Facility · Binding and excavation works at Viewing Platform |

|

· Construction dust and noise generation from construction works and excavation works

· Waste generation from the construction activities

· Dust suppression by regular wetting and water spraying for construction works

· Reduction of noise from equipment and machinery on-site

· Sorting and storage of general refuse and construction waste

|

Works Description |

Location |

|

- 273mm Dia. pipe

piling works at lookout point |

Lookout Point |

|

Installation of steel casing for pre-bored H piles at A1 & A2 |

Landing Facility |

|

Infill Grouting of Pipe Piles |

Lookout Ponit |

|

Construction of Skin Wall and R.C Paving |

Lookout Point |

|

Dredging |

Portion A & D |

|

Stone surface truing |

Viewing Platform (left-side) |

|

Rormwork / Rebar fixing |

Viewing Platform (right-side) |

· Construction dust and noise generation from excavation and construction works

· Waste generation from construction activities

· Impact on water quality from marine construction works and inland construction works

· Dust suppression by regular wetting and water spraying for construction works

· Reduction of noise from equipment and machinery on-site

· Sorting and storage of general refuse and construction waste

· The dredging rate shall not exceed 100 m3 per hour with a maximum working period of 12 hours per day throughout the construction phase and operation phase.

· Silt curtains should be deployed enclosing the dredging operation. Regular inspection on the silt curtain on the silt curtain condition by the contractor should be carried out.

Civil Engineering and Development Department (CEDD) has contracted Concentric - Hong Kong River Joint Venture (CHKRJV) to carry out the Construction of Lei Yue Mun Public Landing Facility under Contract No. CV/2020/09; and Architectural Services Department (ArchSD) has contracted Milestone Builder Engineering Limited to carry out the development of a waterfront promenade and related improvement works under Contract No. SS J521 for the Lei Yue Mun Waterfront Enhancement Project (the Project).

Acuity Sustainability Consulting Limited (ASCL) is commissioned by CEDD to undertake the Environmental Team (ET) services as required and/or implied, both explicitly and implicitly, in the Environmental Permit (EP), Environmental Impact Assessment Report (EIA Report) (Register No. AEIAR-219/2018) and Environmental Monitoring and Audit Manual (EM&A Manual) for the Project; and to carry out the Environmental Monitoring and Audit (EM&A) programme in fulfillment of the EIA Report’s EM&A requirements under Contract No. PI 2/2020.

Pursuant to the Environmental Impact Assessment Ordinance (EIAO), the Director of Environmental Protection granted the Environmental Permit (No. EP-564/2018) to CEDD for the Project.

This is the 3rd Monthly EM&A Report for the Project which summarizes the key findings of the EM&A programme during the reporting period from 1 July to 31 July 2021.

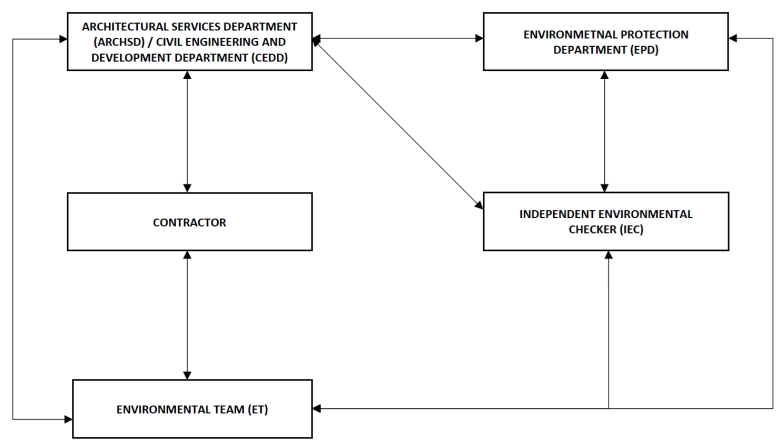

The Project Organization structure for Construction Phase is presented in Figure 1.1. The key personnel’s’ contacts are presented in Table 1.1 and Table 1.2.

Figure 1.1 Project Organization Chart

Table 1.1 Key Personnel’s’ Contact for the Construction of a Public Landing Facility and Improvement Works to Existing Lookout Points and Viewing Platform

|

Party |

Position |

Name |

Phone |

|

Civil Engineering and Development Department |

Engineer |

Ms. Lam Sau Lai, Katy |

2762 5044 |

|

ANewR |

Independent Environmental Checker |

Mr. Choi Pui Sum, James |

2618 2831 |

|

Acuity Sustainability Consulting Limited |

Environmental Team |

Mr. Li Wai Ming, Kevin |

2698 6833 |

|

Concentric - Hong Kong River Joint Venture |

Contractor |

Mr. Cheung C Y, Joe |

9263 6339 |

Table 1.2 Key Personnel’s’ Contact for the Development of a Waterfront Promenade and Related Improvement Works

|

Party |

Position |

Name |

Phone |

|

Architectural Services Department |

Project Manager |

Mr. Ken Chan |

2867 3850 |

|

ANewR |

Independent Environmental Checker |

Mr. Choi Pui Sum, James |

2618 2831 |

|

Acuity Sustainability Consulting Limited |

Environmental Team |

Mr. Li Wai Ming, Kevin |

2698 6833 |

|

Milestone Builder Engineering Ltd. |

Environmental Officer |

Ms. Emily Yim |

6311 1571 |

Details of the major construction activities undertaken in this reporting period are shown as below. The construction programme is presented in Appendix A.

Key activities carried out in this reporting period for the Project included the followings:

|

Location |

|

|

Installation of pipe piles at Lookout Point. |

Lookout Point Area |

|

Marine predrilling works at Breakwater Area. |

Breakwater Area |

|

Installation of pipe piles at landing facility. |

Landing Facility Area |

|

Binding and excavation works at Viewing Platform |

Viewing Platform |

A summary of the valid permits, licences, and/or notifications on environmental protection for this Project is presented in Table 1.3.

Table 1.3 Summary of the Status of Valid Environmental Licence, Notification, Permit and Documentations for the Construction of a Public Landing Facility and Improvement Works to Existing Lookout Points and Viewing Platform

|

Permit/ Licenses/ Notification |

Reference |

Validity Period |

|

Environmental Permit |

EP-564/2018 |

Throughout the Contract |

|

Notification of Construction Works under the Air Pollution Control (Construction Dust) Regulation (Form NA) |

Ref. No.: 463353 |

Throughout the Contract |

|

Chemical Waste Producer Registration |

5213-298-C3752-02 |

Throughout the Contract |

|

Billing Account for Disposal of Construction Waste |

7039364 |

Throughout the Contract |

Table 1.4 Summary of the Status of Valid Environmental Licence, Notification, Permit and Documentations for the Development of a Waterfront Promenade and Related Improvement Works

|

Permit/ Licenses/ Notification |

Reference |

Validity Period |

|

Environmental Permit |

EP-564/2018 |

Throughout the Contract |

|

Notification of Construction Works under the Air Pollution Control (Construction Dust) Regulation (Form NA) |

Ref. No.: 467619 |

Throughout the Contract |

|

Chemical Waste Producer Registration |

5312-298-M2939-02 |

Throughout the Contract |

|

Billing Account for Disposal of Construction Waste |

7039353 |

Throughout the Contract |

The status for all environmental aspects is presented in Table 1.5.

Table 1.5 Summary of Status for Key Environmental Aspects under the EM&A Manual

|

The baseline monitoring result has been reported in Baseline Monitoring Report and submitted to EPD under EP Condition 3.3 on 25 May 2021 |

|

|

N/A as marine works have not commenced yet |

|

|

The baseline monitoring result has been reported in Baseline Monitoring Report and submitted to EPD under EP Condition 3.3 on 25 May 2021 |

|

|

Noise Management Plan |

The Noise Management Plan was submitted by the Contractor on 4 May 2021 and approved on 10 May 2021 |

|

Ecology |

|

|

Conceptual Landscape Layout Plan |

The Conceptual Landscape Layout Plan will be submitted no later than three months prior to the commencement of detailed design of the landscape and architectural works of the Project under EP Condition 2.10 |

|

Coral Baseline Survey Report |

The Coral Baseline Survey Report was submitted to EPD under EP Condition 2.14 on 12 May 2021 and approved by EPD on 18 May 2021 |

|

Coral Translocation Plan |

The Coral Translocation Plan was submitted to EPD under EP Condition 2.16 on 28 April 2021 and approved on 18 May 2021 |

|

Coral Review Report |

The Coral Review Report will be submitted no later than three months before the commencement of each maintenance dredging under EP Condition 2.20 |

|

Site Inspection covering Measures of Air Quality, Noise Impact, Water Quality, Waste, Ecological Quality, Fisheries, Landscape and Visual |

|

Other than the EM&A work by ET, environmental briefings, trainings and regular environmental management meetings were conducted, in order to enhance environmental awareness and closely monitor the environmental performance of the contractors.

The EM&A programme has been implemented in accordance with the recommendations presented in the approved EIA Report and the EM&A Manual. A summary of implementation status of the environmental mitigation measures for the construction phase of the Project during the reporting period is provided in Appendix B.

To ensure no adverse noise impact, noise monitoring is recommended to be carried out within 300m radius from the nearby noise sensitive receivers (NSRs), during construction phase. The NSRs selected as monitoring station are (i) NM1 – Village house in Lei Yue Mun Hoi Pong Road Central, (ii) NM2-A – No.79B, Lei Yue Mun Hoi Pong Road East, (iii) NM3 – Jockey Club Lei Yue Mun Plus and (iv) NM4 – No. 21C, Lei Yue Mun Hoi Pong Road East respectively.

In accordance with the EM&A Manual, baseline noise level at the noise monitoring stations were established as presented in the Baseline Monitoring Report. Impact noise monitoring was conducted once per week in the form of 30-minutes measurements Leq, L10 and L90 levels recorded at each monitoring station between 0700 and 1900 on normal weekdays.

Five (5) sessions of noise monitoring were carried out at the monitoring locations sited at LYM in the reporting month. The results are presented in Appendix F.

Construction noise level were measured in terms of the A-weighted equivalent continuous sound pressure level (LAeq). Leq 30min was used as the monitoring parameter for the time period between 0700 and 1900 on normal weekdays. Table 2.1 summarizes the monitoring parameters, frequency and duration of the impact noise monitoring.

Table 2.1 Noise Monitoring Parameters, Time, Frequency and Duration

|

Time |

Duration |

Interval |

Parameters |

|

Daytime: 0700-1900 |

Day time: 0700-1900 (during normal weekdays) |

Continuously in Leq 5min/Leq 30min (average of 6 consecutive Leq 5min) |

Leq 30min L10 30min & L90 30min |

The monitoring locations should normally be made at a point 1m from the exterior of the NSRs building façade and be at a position 1.2m above the ground. A correction of +3dB(A) should be made to the free-field measurements.

According to the environmental findings detailed in the EIA report and Baseline Monitoring Report, the designated locations for the construction noise monitoring are listed in Table 2.2 below.

Table 2.2 Noise Monitoring Locations

|

Station |

Noise Monitoring Stations |

Monitoring Location |

Position |

|

NM1 |

Village house in Lei Yue Mun Hoi Pong Road Central |

Pedestrian Road on Ground Floor |

1 m from facade |

|

NM2 |

No.81, Lei Yue Mun Hoi Pong Road East |

Pedestrian Road on Ground Floor |

1 m from facade |

|

NM3 |

Jockey Club Lei Yue Mun Plus |

Fenced Road on Ground Floor |

1 m from facade |

|

NM4 |

No. 21C, Lei Yue Mun Hoi Pong Road East |

Fenced Road on Ground Floor |

1 m from facade |

The original construction noise monitoring station NM2 was selected at the façade of No. 81 of Lei Yue Mun Hoi Pong Road East. However, the residents of the premises at No. 81 of Lei Yue Mun Hoi Pong Road East do not allow the setting up of the construction noise monitoring station NM2. No. 79B, Lei Yue Mun Hoi Pong Road East, was proposed as the alternative noise monitoring location for set up of construction noise monitoring station named as NM2-A.

A Proposal for Alternative Noise Monitoring Station, which was certified by the ET Leader and verified by the IEC, has been prepared to conclude that the alternative construction noise monitoring station NM2-A could conform to relevant requirements as set out in the EM&A Manual, namely:

· locate close to the major site activities which are likely to have noise impacts;

· locate close to the most affected existing NSRs; and

· take into account the possibility of minimizing disturbance to occupants at the NSRs during monitoring.

The Proposal for Alternative Noise Monitoring Station NM2-A has been approved by EPD on 16 April 2021.

The latest locations for the construction noise monitoring are listed in Table 2.3.

Table 2.3 Updated Noise Monitoring Stations for Baseline and Impact Monitoring

|

Station |

Noise Sensitive Receiver |

Monitoring Location |

Position |

|

NM1 |

Village house in Lei Yue Mun Hoi Pong Road Central |

Pedestrian Road on Ground Floor |

1 m from facade |

|

NM2-A |

No.79B, Lei Yue Mun Hoi Pong Road East |

Pedestrian Road on Ground Floor |

1 m from facade |

|

NM3 |

Jockey Club Lei Yue Mun Plus |

Fenced Road on Ground Floor |

1 m from facade |

|

NM4 |

No. 21C, Lei Yue Mun Hoi Pong Road East |

Fenced Road on Ground Floor |

1 m from facade |

The location of all original construction noise

monitoring stations and the alternative construction noise monitoring station

are shown in Figure 2.1.

|

|

Figure 2.1 Noise Monitoring Locations |

Integrated sound level meter shall be used for the noise monitoring. The meter shall be in compliance with the International Electrotechnical Commission Publications 651: 1979 (Type 1) and 804: 1985 (Type 1) specifications. Immediately prior to and following each noise measurement the accuracy of the sound level meter shall be checked using an acoustic calibrator generating a known sound pressure level at a known frequency. Measurements may be accepted as valid only if the calibration levels before and after the noise measurements agree to within 1.0 dB(A). Calibration certificates of the instruments used are shown at Appendix E.

Noise measurements shall not be made in the presence of fog, rain, wind with a steady speed exceeding 5 m/s or wind with gusts exceeding 10 m/s. The wind speed shall be checked with a portable wind speed meter capable of measuring the wind speed in m/s.

Table 2.4 Impact Noise Monitoring Equipment

|

Equipment |

Make and Model |

|

Sound Level Meter |

Scarlet ST-11D |

The Action/Limit Levels are in line with the criteria of Practice Note for Professional Persons (ProPECC PN 2/93) “Noise from Construction Activities – Non-statutory Controls” and Technical Memorandum on Environmental Impact Assessment Process issued by HKSAR Environmental Protection Department [“EPD”] under the Environmental Impact Assessment Ordinance, Cap 499, S.16 are presented in Table 2.5.

Table 2.5 Action and Limit Levels for Noise per EM&A Manual

|

Time Period |

Action |

Limit (dB(A)) |

|

0700-1900 on normal weekdays |

When one documented complaint is received from any one of the noise sensitive receivers |

75 dB(A) for residential areas; 70 dB(A) for school; and 65 dB(A) during examination period |

Notes: Limits specified in the GW-TM and IND-TM for construction and operation noise, respectively.

If exceedances were found during noise monitoring, the actions in accordance with the Event and Action Plan shall be carried out according to Appendix D.

Referring to EM&A manual Section 4.6.1.1 construction noise monitoring should be carried out when there are project-related construction activities undertaken within a radius of 300m from the monitoring stations. Five (5) sessions of noise monitoring were carried out at the monitoring locations sited at LYM in the reporting month. The below Table 2.6 summarized the results of the monitoring.

Table 2.6 Summary of Noise Monitoring Results in the Reporting Month

|

Noise in dB(A) |

|

|

Leq 30min Daytime (7:00-19:00 on normal weekdays) |

|

|

NM1 |

59.0 – 71.1 |

|

NM2-A |

60.2 – 62.1 |

|

NM3 |

66.2 – 69.1* |

|

NM4 |

63.7 – 64.5 |

Notes: *The noise monitoring result carried out at NM3 on 7 July 2021 was higher than the daytime construction criterion. However, this result is not considered as an exceedance as it is below the limit level after deducting the baseline noise level.

As identified in the EIA Report, suspended sediment is the most critical water quality parameter caused by the dredging works. Marine water quality monitoring should be carried out during the dredging and filling operation to ensure that any unacceptable increase in suspended solids / turbidity and decrease in dissolved oxygen due to the dredging activities could be readily detected and timely action be taken to rectify the situation. In addition, baseline water quality monitoring was conducted prior to the commencement of marine construction activities. The following Section provides details of the water quality monitoring to be undertaken by the Environmental Team (ET). The water quality monitoring programme will be carried out to allow any deteriorating water quality to be readily detected and timely action taken to rectify the situation.

As the construction of marine-based works are scheduled to commence in mid-August 2021 tentatively, no water quality monitoring was conducted in the reporting month.

The parameters that have been selected for measurement in situ and in the laboratory are those that were either determined in the EIA to be those with the most potential to be affected by the construction works or are a standard check on water quality conditions. Parameters to be measured in the impact monitoring are listed in Table 3.1.

Table 3.1 Parameters measured in the marine water quality monitoring

|

Parameters |

Unit |

Abbreviation |

|

In-situ measurements |

||

|

Dissolved oxygen |

mg/L |

DO |

|

Temperature |

oC |

- |

|

pH |

- |

- |

|

Turbidity |

NTU |

- |

|

Salinity |

mg/L |

- |

|

Laboratory measurements |

||

|

Suspended Solids |

mg/L |

SS |

For water quality monitoring, the following equipment will be used:

Dissolved Oxygen and Temperature Measuring Equipment - The instrument will be a portable, weatherproof dissolved oxygen measuring instrument complete with cable, sensor, comprehensive operation manuals, and will be operable from a DC power source. It will be capable of measuring: dissolved oxygen levels in the range of 0 - 20 mg/L and 0 - 200% saturation; and a temperature of 0 - 45 degrees Celsius. It shall have a membrane electrode with automatic temperature compensation complete with a cable of not less than 35 m in length. Sufficient stocks of spare electrodes and cables shall be available for replacement where necessary (e.g. YSI model 59 DO meter, YSI 5739 probe, YSI 5795A submersible stirrer with reel and cable or an approved similar instrument).

Turbidity Measurement Equipment - The instrument will be a portable, weatherproof turbidity-measuring unit complete with cable, sensor and comprehensive operation manuals. The equipment will be operated from a DC power source, it will have a photoelectric sensor capable of measuring turbidity between 0 - 1000 NTU and will be complete with a cable with at least 35 m in length (for example Hach 2100P or an approved similar instrument).

pH Measurement Instrument - The instrument should consist of a potentiometer, a glass electrode, a reference electrode and a temperature-compensating device. It should be readable to 0.1 pH in a range of 0 to 14. Standard buffer solutions of at least pH 7 and pH 10 should be used for calibration of the instrument before and after use.

Salinity Measurement Instrument - A portable salinometer capable of measuring salinity in the range of 0 - 40 ppt will be provided for measuring salinity of the water at each monitoring location.

Sample Containers and Storage - Water samples for SS should be stored in high density polythene bottles with no preservative added, packed in ice (cooled to 4 °C without being frozen) and delivered to the laboratory and analyzed as soon as possible after collection. Sufficient volume of samples should be collected to achieve the detection limit.

Water Depth Gauge – A portable, battery-operated echo sounder (for example Seafarer 700 or a similar approved instrument) will be used for the determination of water depth at each designated monitoring station. This unit will preferably be affixed to the bottom of the work boat if the same vessel is to be used throughout the monitoring programme. The echo sounder should be suitably calibrated. The ET shall seek approval for their proposed equipment with the client prior to deployment.

Positioning Device – A Global Positioning System (GPS) shall be used during monitoring to allow accurate recording of the position of the monitoring vessel before taking measurements. The Differential GPS, or equivalent instrument, should be suitably calibrated at appropriate checkpoint (e.g. Quarry Bay Survey Nail) to verify that the monitoring station is at the correct position before the water quality monitoring commence.

Water Sampling Equipment - A water sampler, consisting of a PVC or glass cylinder of not less than two litres, which can be effectively sealed with cups at both ends, will be used (e.g. Kahlsico Water Sampler 13SWB203 or an approved similar instrument). The water sampler will have a positive latching system to keep it open and prevent premature closure until released by a messenger when the sampler is at the selected water depth.

All in situ monitoring instruments will be checked, calibrated and certified by a laboratory accredited under HOKLAS or any other international accreditation scheme before use, and subsequently re-calibrated at monthly intervals throughout the stages of the water quality monitoring. Responses of sensors and electrodes will be checked with certified standard solutions before each use.

On-site calibration of field equipment shall follow the “Guide to On-Site Test Methods for the Analysis of Waters”, BS 1427: 2009. Sufficient stocks of spare parts shall be maintained for replacements when necessary. Backup monitoring equipment shall also be made available so that monitoring can proceed uninterrupted even when equipment is under maintenance, calibration etc.

All laboratory work shall be carried out in a HOKLAS accredited laboratory. Sufficient volume of each water sample shall be collected at the monitoring stations for carrying out the laboratory analyses. Using chain of custody forms, collected water samples will be transferred to an HOKLAS accredited laboratory for immediate processing. The determination work shall start within 24 hours after collection of the water samples. The laboratory measurements shall be provided to the client within 5 working days of the sampling event. Analytical methodology and sample preservation of other parameters will be based on the latest edition of Standard Methods for the Examination of Waste and Wastewater published by APHA, AWWA and WPCF and methods by USEPA, or suitable method in accordance with requirements of HOKLAS or another internationally accredited scheme.

Detailed testing methods, pre-treatment procedures, instruments use, Quality Assurance / Quality Control (QA/QC) details (such as blank, spike recovery, number of replicate samples per batch, etc.), detection limit and accuracy were submitted to EPD for approval on 3 February 2021 prior to the commencement of monitoring programme. EPD may also request the laboratory to carry out analysis of known standards provided by EPD for quality assurance. The QA / QC shall be in accordance with the requirements of HOKLAS or international accredited scheme. The QA/ QC results shall be reported. The testing methods and related proposal were checked and certified by IEC before submission to EPD for approval.

Parameters for laboratory measurements, their standard methods and their detection limits are presented in Table 3.2.

Table 3.2 Laboratory measurements, standard methods and corresponding detection limits of marine water quality monitoring

|

Parameter |

Standard Method |

Detection Limit |

Accuracy |

|

Suspended Solids (mg/L) |

APHA 2540D |

1.0* |

±17% |

Remark *: Albeit the selected HOKLAS accredited laboratories’ standard testing method of total suspended solid according to APHA Method 2540D is capable of reporting the results to 1 mg/L, the laboratory advised that results reported between 1 and 2 mg/L shall be considered to be used as reference value and receive no HOKLAS accreditation for this particular range of result

If exceedances were found during water monitoring, the actions in accordance with the Event and Action Plan shall be carried out according to Appendix G.

The water quality monitoring locations for baseline are in accordance to the EM&A Manual and detailed in Table 3.3 below. The water quality monitoring schedule should be submitted to EPD at least 1 week before the first day of the monitoring month.

Table 3.3 Location of Water Quality Monitoring Station

|

Station |

Easting |

Northing |

Description |

|

C1 |

842134 |

816765 |

Control Station |

|

C2 |

842946 |

816172 |

Control Station |

|

M1 |

842605 |

816433 |

Coral Communities (Impact Monitoring Station) |

|

M2 |

842329 |

816615 |

100m away from the dredging site (Impact Monitoring Station) |

|

M3 |

842639 |

816410 |

Coral Communities (Impact Monitoring Station) |

|

M4 |

842515 |

816878 |

Sam Ka Tsuen Typhoon Shelter (Impact Monitoring Station) |

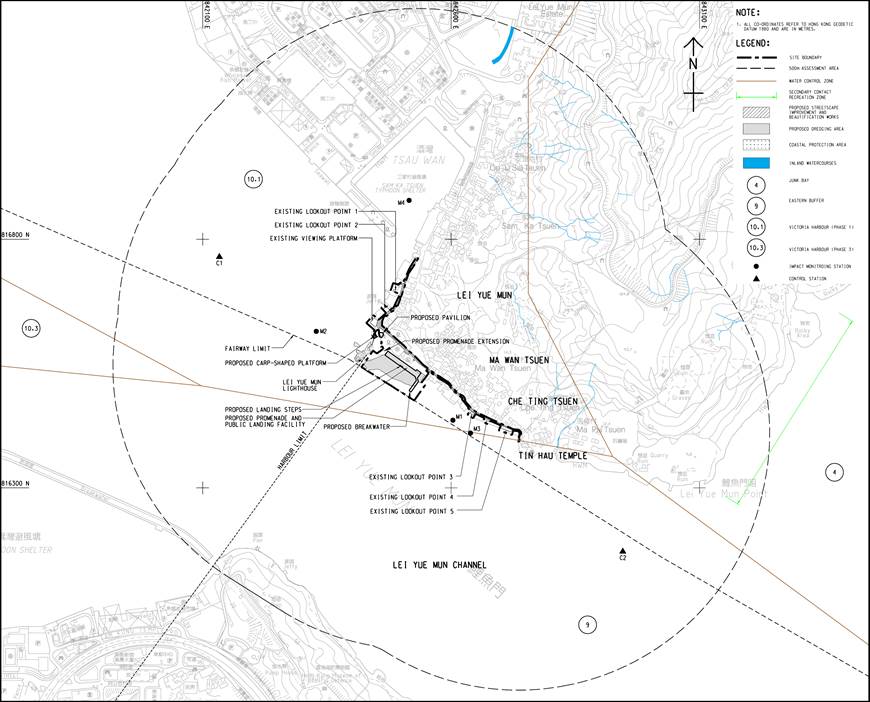

Figure 3.1 Water quality monitoring locations under EM&A Manual

During periods when there are dredging or filling works, impact monitoring should be undertaken at the monitoring stations as shown in Figure 3.1 and Table 3.3 three days per week during the construction phase after the commencement of marine construction works and dredging or filling activities. Monitoring at each station would be undertaken at both mid-ebb and mid-flood tides on the same day. The interval between two sets of monitoring would not be less than 36 hours. The monitoring frequency would be increased in the case of exceedances of Action/Limit Levels if considered necessary by ET. Monitoring frequency would be maintained as far as practicable.

For water quality monitoring, each station will be sampled and measurements/ water samples will be taken at three depths, 1 m below the sea surface, mid-depth and 1 m above the seabed. For stations that are less than 3 m in depth, only the mid depth sample shall be taken. For stations that are less than 6 m in depth, only the surface and seabed sample shall be taken. For in situ measurements, duplicate readings shall be made at each water depth at each station. Duplicate water samples shall be collected at each water depth at each station.

The Action and Limit Levels have been set based on the derivation criteria specified in the EM&A Manual, as shown in Table 3.4 below. Based on the baseline water quality monitoring data and the derivation criteria specified in Table 3.4, the Action/Limit Levels have been derived and are presented in Table 3.5.

The ET of the Project had conducted the baseline water monitoring between 15 April 2021 to 11 May 2021 at all six designated monitoring stations (i.e. C1, C2, M1, M2, M3 and M4). The monitoring results was presented in Baseline Water Quality Monitoring Report separately.

The commencement of marine construction activities for the Project is expected to be commenced in mid-August 2021.

Table 3.4 Criteria of Action and Limit Levels for Water Quality

|

Parameters |

Action |

Limit |

|

During the Dredging and Filling Operation of the Project |

||

|

DO in mg/L |

Surface and Middle ≤5%-ile of baseline data for surface and middle layers Bottom ≤5%-ile of baseline data for bottom layer |

Surface and Middle ≤4 mg/L or 1%-ile of baseline data for surface and middle layers Bottom ≤2 mg/L or 1%-ile of baseline data for bottom layer |

|

SS in mg/L (Depth-averaged) |

≥ 95 %-ile of baseline data or 120% of control station’s SS at the same tide of the same day |

≥ 99 %-ile of baseline data or 130% of control station’s SS at the same tide of the same day and specific sensitive receiver water quality requirements (e.g. required SS level for concerned seawater intakes) |

|

Turbidity in NTU (Depth-averaged) |

≥ 95 %-ile of baseline data or 120% of control station’s SS at the same tide of the same day |

≥ 99 %-ile of baseline data or 130% of control station’s SS at the same tide of the same day |

Table 3.5 Derived Action and Limit Levels for Water Quality

|

Parameters |

Action |

Limit |

|

During the Dredging and Filling Operation of the Project |

||

|

DO in mg/L |

Surface and Middle 7.95 mg L-1 Bottom 7.91 mg L-1 |

Surface and Middle 4 mg L-1 Bottom 2 mg L-1 |

|

SS in mg/L (Depth-averaged) |

6.73 mg L-1 or 120% of control station’s SS at the same tide of the same day |

17.60 mg L-1 or 130% of control station’s SS at the same tide of the same day and specific sensitive receiver water quality requirements (e.g. required SS level for concerned seawater intakes) |

|

Turbidity in NTU (Depth-averaged) |

7.42 NTU or 120% of control station’s SS at the same tide of the same day compared with corresponding data from control station |

7.79 NTU or 130% of control station’s SS at the same tide of the same day compared with corresponding data from control station |

Notes:

i. "Depth-averaged" is calculated by taking the arithmetic means of reading of all three depths.

ii. For DO, non-compliance of the water quality limits occurs when monitoring result is lower than the limits.

iii. For Turbidity, SS and Salinity, non-compliance of the water quality limits occurs when monitoring result is higher than the limits.

No water quality monitoring was conducted in the reporting period because marine-based works was scheduled to commence in mid-August 2021.

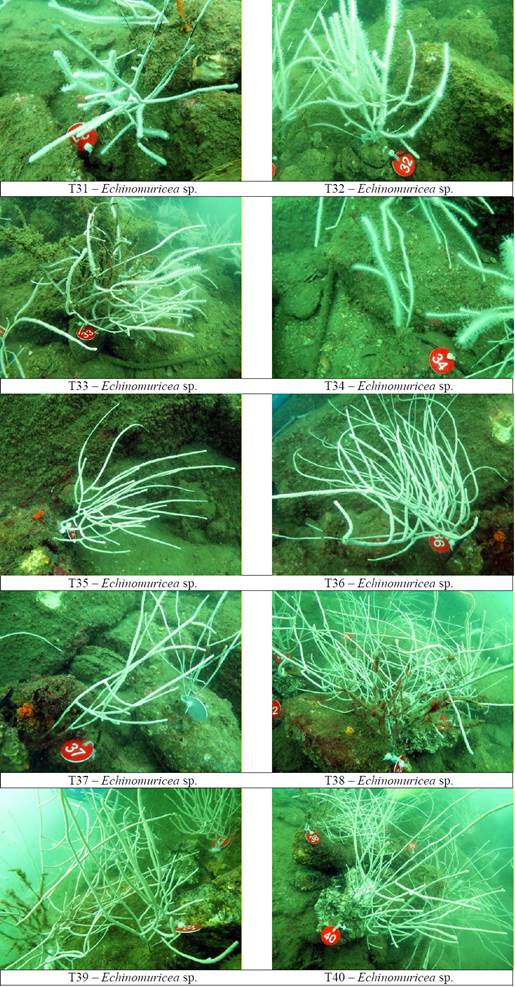

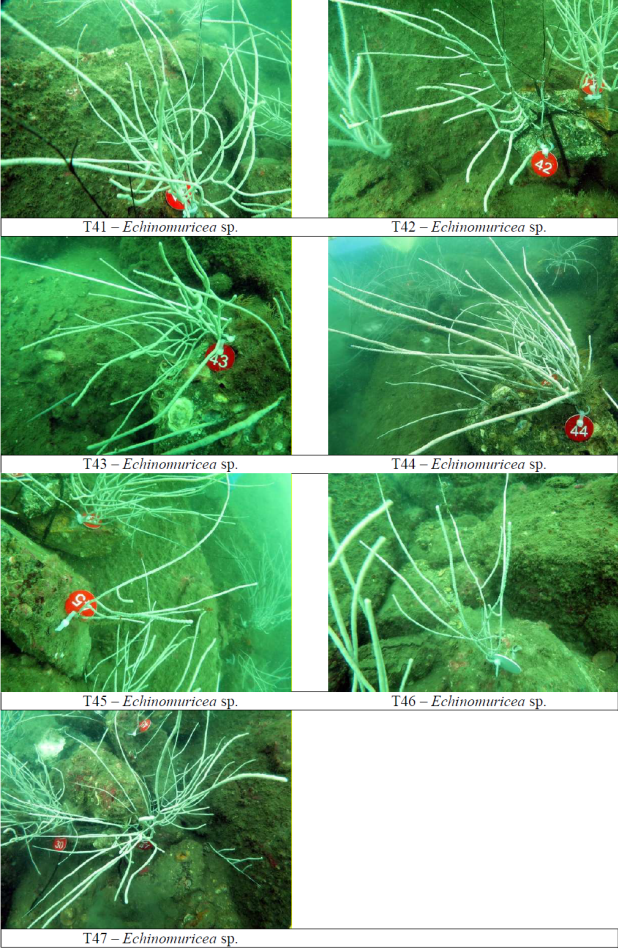

Tagging of Reference Coral Colonies at the Recipient Site

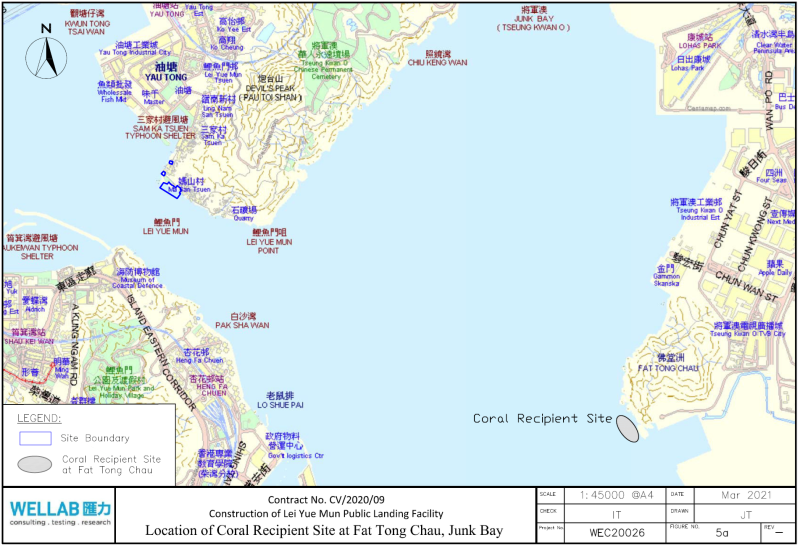

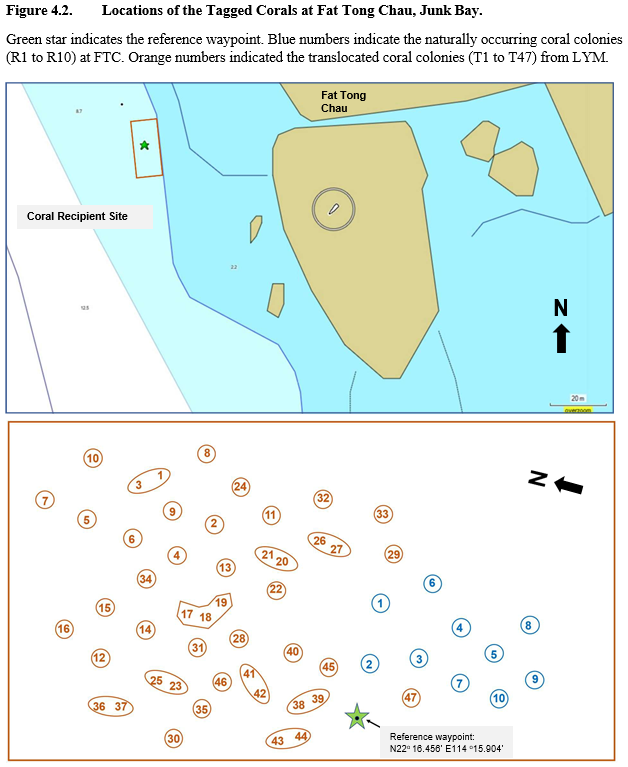

The coral translocation was conducted on 20 and 21 May 2021. A total of 47 coral colonies were translocated from the donor site (Lei Yue Mun) to the recipient site Fat Tong Chau (FTC), Junk Bay. The location of the recipient site is shown in Figure 4.1.

To distinguish the effect of the translocation exercise on the translocated coral colonies against the natural variation in health status at the recipient location, comparison of health status between the translocated colonies and original colonies in the recipient location shall be performed.

Simultaneous monitoring of the 2 groups of colonies will help evaluating the potential sources of impact to the colonies if deteriorating in health condition is recorded. Colonies to be tagged were giving priority to the large, undamaged colonies since damage to these colonies would be more evident compared to smaller colonies or corals with existing damage.

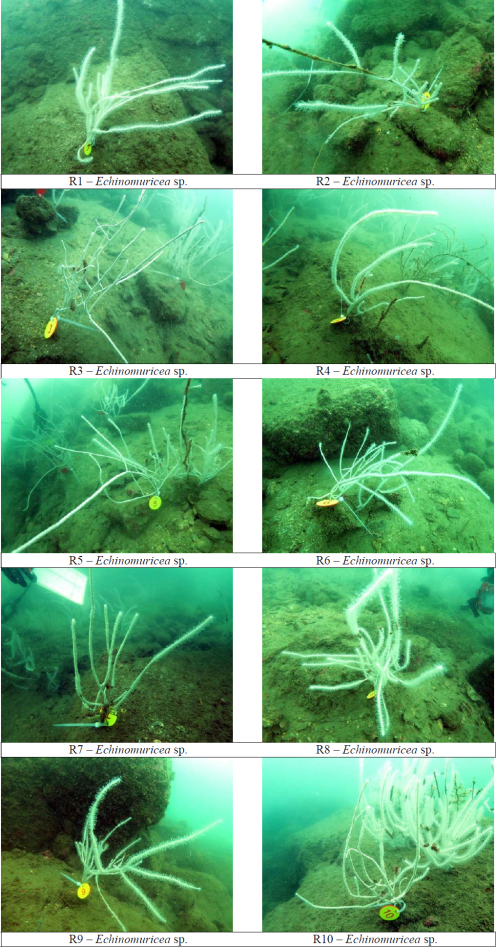

At the recipient site, ten (10) octocoral colonies of Echinomuricea sp. were tagged and used as reference colonies for monitoring after the coral translocation. Each selected colony was tagged with plastic tags using cable ties.

For each tagged coral colony, detailed information was recorded including its location, species name, size, and health status information including sedimentation level (percentage cover and thickness of sediments), percentage cover of partial mortality and bleaching.

The condition of each tagged coral colony was recorded by taking a photograph from an angle and distance that best represents the entire colony. All field data were collected by a qualified marine ecologist using SCUBA dive.

Figure 4.1 Location of Coral Recipient Site at Fat Tong Chau, Junk Bay

Translocation and Tagging of Coral Colonies from the Donor Site

Coral translocation from donor site to recipient site was performed with multiple measures to minimize stress and damage to the colonies, under the guidance of a marine ecologist with relevant experience.

All movable boulders with the translocated coral colonies at donor location were moved entirely as a whole object into a tray or bucket, and lifted from sea bottom to water surface using lifting bag by SCUBA divers. All the coral colonies attached on the boulders were kept submerged at all time with a brief exposure unavoidable when transferred onto the vessel.

The translocated colonies transferred onto the vessel were submerged in seawater tanks (of considerable size, e.g. 100 cm x 80 cm x 40 cm in dimension and 32 liters in volume each) with continuous aeration onboard. Each seawater tank held no more than 5 boulders to avoid overcrowding. Shading was provided by placing the tanks under roof of the vessel to avoid exposure to direct sunlight.

Ambient water quality parameters of sea surface temperature and dissolved oxygen were measured once (with at least 3 replicate sampling) at donor location on the day of coral translocation. The seawater quality in the tank was checked every 15 minutes to ensure no fluctuation above 10% ambient occurs to the seawater in which the corals were submerged.

Each coral colony was tagged with plastic tags using cable ties. Corals were transported to the recipient site immediately on the same day after the removal. Speed of the vessel was kept <5 knots during the moving exercise. During the course of transportation, all the coral colonies were kept submerged at all time; the orientation of boulder and corals in the seawater tanks was checked every 15 minutes to ensure coral colonies would not be damaged on the way to the recipient location.

Once arrived at the recipient site, the translocated colonies were placed one by one onto the seabed. Colonies were positioned to similar depths with orientations as their previous location at the donor sites as far as possible.

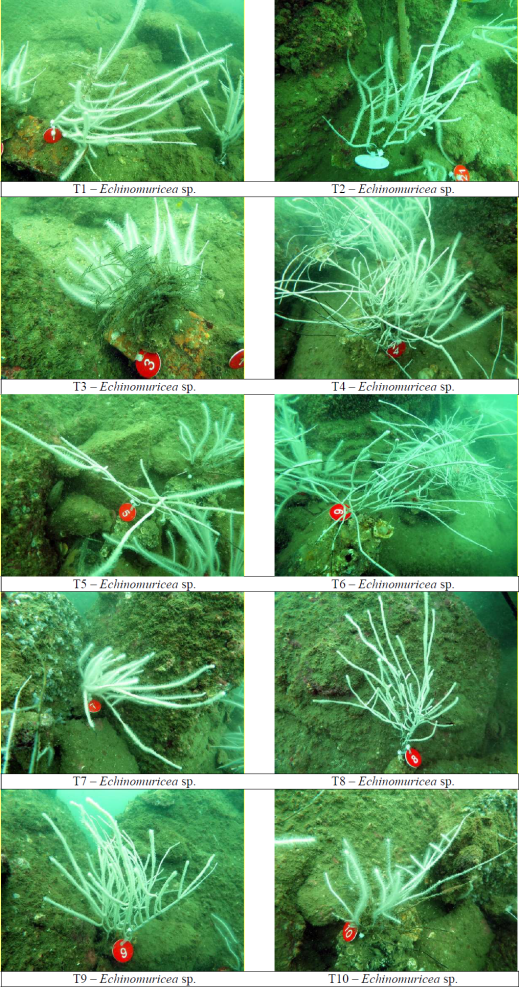

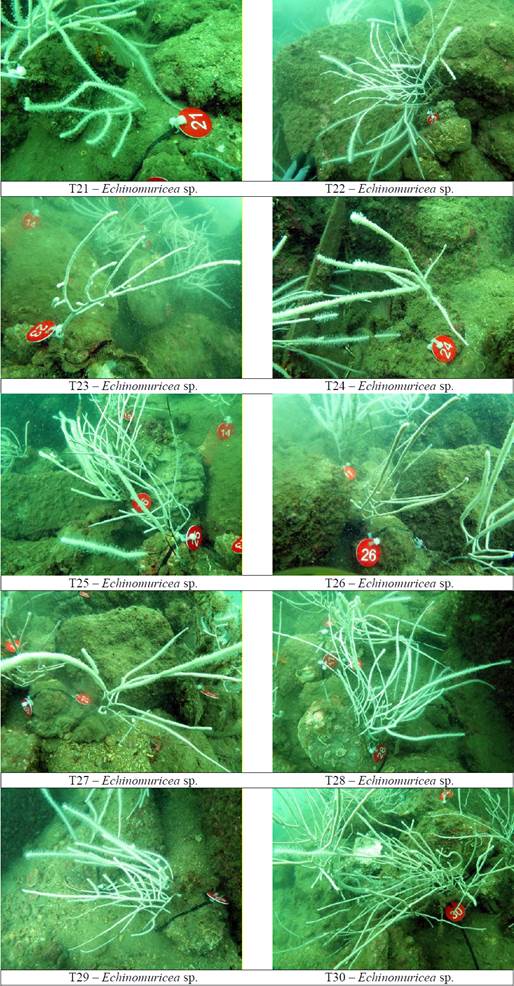

A Post-translocation coral survey was conducted after the completion of the translocation work. The status of each translocated coral colony including size, location, health conditions (sedimentation, bleaching and partial mortality) were recorded. Photographs of each translocated coral were taken as baseline for future monitoring.

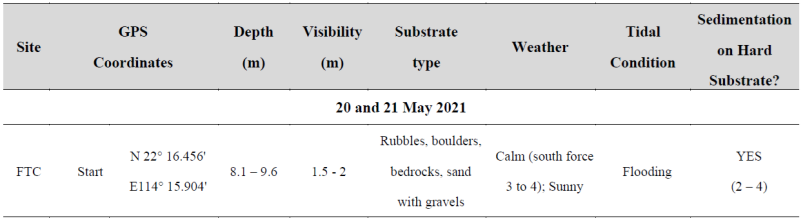

The post-translocation coral survey was conducted on 21 May 2021 to monitor the health status of the tagged translocated coral colonies and tagged natural coral colonies at the recipient site Fat Tong Chau (FTC), Junk Bay.

The coral suevey was conducted by two SCUBA divers and at least one of them was a coral specialist. During the survey, the health status of each tagged coral colony was recorded, including percentage cover (%) of (1) mortality; (2) bleaching and (3) sedimentation.

The condition of each tagged coral colony was recorded by taking a photograph from an angle and distance that best represents the entire colony.

The results of this post-translocation coral survey provide a reference for the post-translocation monitoring to be conducted by Environmental Team (ET) at Months 3, 6, 9 and 12 after the coral translocation according to Condition 2.16 of the Environmental Permit No. EP-564/2018 and Clause 9.4.1.5 of Environmental Monitoring and Audit Manual.

The coming regular post-translocation monitoring will be conducted in August 2021 to assess the status of the translocated colonies according to the proposed monitoring frequency and method stated above. 10 selected translocated coral colonies (21% of all translocated corals) shall be monitored for comparison with the tagged natural coral colonies. The method of selecting 10-30% of all translocated corals for regular post-translocation monitoring is a common practice for some other EIA projects, such as the Airport Artificial Island Coral Translocation (2020), the 3rd Runway Coral Translocation (2019), etc.

Echinomuricea sp. was the only species present and tagged as natural coral colonies at the translocation recipient location. To better compare between the natural coral colonies and the translocated coral colonies, 10 healthy Echinomuricea sp. will be selected by the Coral Specialist for monitoring.

The coral translocation was conducted on 20 and 21 May 2021. After the coral translocation, a Post-translocation Coral Survey, at recipient site FTC, was conducted on 21 May 2021. The location of the recipient site is shown in Figure 4.1.

The environmental conditions of the recipient site FTC are presented in Table 4.1 below.

Table 4.1 Location and Physical Attributes of the Coral Recipient Site at FTC, Junk Bay

![]() The code, species

name, size, percentage of mortality, bleaching and sedimentation of the tagged coral colonies at the recipient

site are summarized in Tables 4.2

and 4.3. The new locations of the translocated corals, and tagged naturally

occurring corals at recipient site, are presented in Figure 4.2.

The code, species

name, size, percentage of mortality, bleaching and sedimentation of the tagged coral colonies at the recipient

site are summarized in Tables 4.2

and 4.3. The new locations of the translocated corals, and tagged naturally

occurring corals at recipient site, are presented in Figure 4.2.

Photographs of the colonies, taken on 21 May 2021, are shown in Figures 4.3 and 4.4. The survey team had tried to take photographs of the corals from an angle and distance that best represented the colonies, but difficulties sometimes occurred as a result of low water visibility during the survey.

Tagged Corals Naturally Occurring in Recipient Site

The general health conditions (size, condition, mortality, bleaching and sedimentation) of ten (10) tagged naturally occurring coral colonies (R1 to R10) were recorded and summarized in Table 4.2.

All coral colonies were in good condition, showed no mortality, bleaching or sedimentation. Photographs of the tagged colonies naturally occurring in the recipient site are shown in Figure 4.3.

Tagged Translocated Corals in Recipient Site

A total of forty-seven (47) octocoral colonies, including 46 colonies of Echinomuricea sp. and 1 colony of Menella sp., were translocated from the donor site LYM to the coral recipient site FTC, Junk Bay.

The general health conditions (size, condition, mortality, bleaching and sedimentation) of the tagged translocated coral colonies (T1 to T47) were recorded and summarized in Table 4.3.

Almost all coral colonies were in good condition, only four colonies (T11, T25, T33 and T38), which were in fair condition, showed low level of mortality from 5 to 10%. Photographs of the tagged translocated corals in the recipient site are shown in Figure 4.4.

Table 4.2 Tagged Naturally

Occurring Corals (Reference Corals) – Percentage of Mortality, Bleaching, and Sedimentation

of the Tagged Coral Colonies in the Post-translocation Coral Survey (21 May 2021)

Table 4.2 Tagged Naturally

Occurring Corals (Reference Corals) – Percentage of Mortality, Bleaching, and Sedimentation

of the Tagged Coral Colonies in the Post-translocation Coral Survey (21 May 2021)

Table 4.3 Tagged Translocated Coral Colonies – Percentage of Mortality, Bleaching, and Sedimentation of the Tagged Coral Colonies in the Post-translocation Coral Survey (21 May 2021)

|

Code |

Coral Species |

Size (Max. height, cm) |

General Condition |

Mortality, % |

Bleaching, % |

Sedimentation, % (Thickness, mm) |

|

T1 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T2 |

Echinomuricea sp. |

15 |

Good |

0 |

0 |

0 |

|

T3 |

Echinomuricea sp. |

15 |

Good |

0 |

0 |

0 |

|

T4 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T5 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T6 |

Echinomuricea sp. |

25 |

Good |

0 |

0 |

0 |

|

T7 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T8 |

Echinomuricea sp. |

25 |

Good |

0 |

0 |

0 |

|

T9 |

Echinomuricea sp. |

15 |

Good |

0 |

0 |

0 |

|

T10 |

Echinomuricea sp. |

15 |

Good |

0 |

0 |

0 |

|

T11 |

Echinomuricea sp. |

20 |

Fair |

10 |

0 |

0 |

|

T12 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T13 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T14 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T15 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T16 |

Echinomuricea sp. |

25 |

Good |

0 |

0 |

0 |

|

T17 |

Echinomuricea sp. |

25 |

Good |

0 |

0 |

0 |

|

T18 |

Menella sp. |

30 |

Good |

0 |

0 |

0 |

|

T19 |

Echinomuricea sp. |

25 |

Good |

0 |

0 |

0 |

|

T20 |

Echinomuricea sp. |

30 |

Good |

0 |

0 |

0 |

|

T21 |

Echinomuricea sp. |

15 |

Good |

0 |

0 |

0 |

|

T22 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T23 |

Echinomuricea sp. |

25 |

Good |

0 |

0 |

0 |

|

T24 |

Echinomuricea sp. |

15 |

Good |

0 |

0 |

0 |

|

T25 |

Echinomuricea sp. |

20 |

Fair |

5 |

0 |

0 |

|

T26 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T27 |

Echinomuricea sp. |

25 |

Good |

0 |

0 |

0 |

|

T28 |

Echinomuricea sp. |

25 |

Good |

0 |

0 |

0 |

|

T29 |

Echinomuricea sp. |

15 |

Good |

0 |

0 |

0 |

|

T30 |

Echinomuricea sp. |

35 |

Good |

0 |

0 |

0 |

|

T31 |

Echinomuricea sp. |

15 |

Good |

0 |

0 |

0 |

|

T32 |

Echinomuricea sp. |

15 |

Good |

0 |

0 |

0 |

|

T33 |

Echinomuricea sp. |

15 |

Fair |

5 |

0 |

0 |

|

T34 |

Echinomuricea sp. |

15 |

Good |

0 |

0 |

0 |

|

T35 |

Echinomuricea sp. |

25 |

Good |

0 |

0 |

0 |

|

T36 |

Echinomuricea sp. |

30 |

Good |

0 |

0 |

0 |

|

T37 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T38 |

Echinomuricea sp. |

25 |

Fair |

5 |

0 |

0 |

|

T39 |

Echinomuricea sp. |

30 |

Good |

0 |

0 |

0 |

|

T40 |

Echinomuricea sp. |

35 |

Good |

0 |

0 |

0 |

|

T41 |

Echinomuricea sp. |

35 |

Good |

0 |

0 |

0 |

|

T42 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T43 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T44 |

Echinomuricea sp. |

35 |

Good |

0 |

0 |

0 |

|

T45 |

Echinomuricea sp. |

25 |

Good |

0 |

0 |

0 |

|

T46 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

|

T47 |

Echinomuricea sp. |

20 |

Good |

0 |

0 |

0 |

Figure 4.3 Tagged Coral Colonies Naturally Occurring at Recipient Site FTC, Junk Bay

Figure 4.4 Tagged Translocated Coral Colonies at FTC, Junk Bay

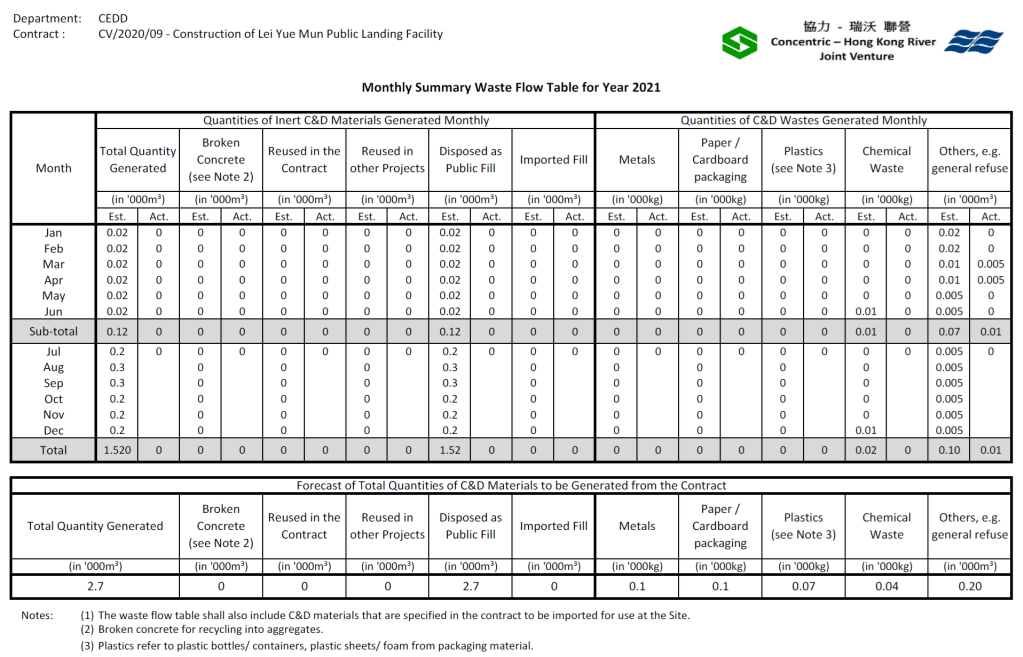

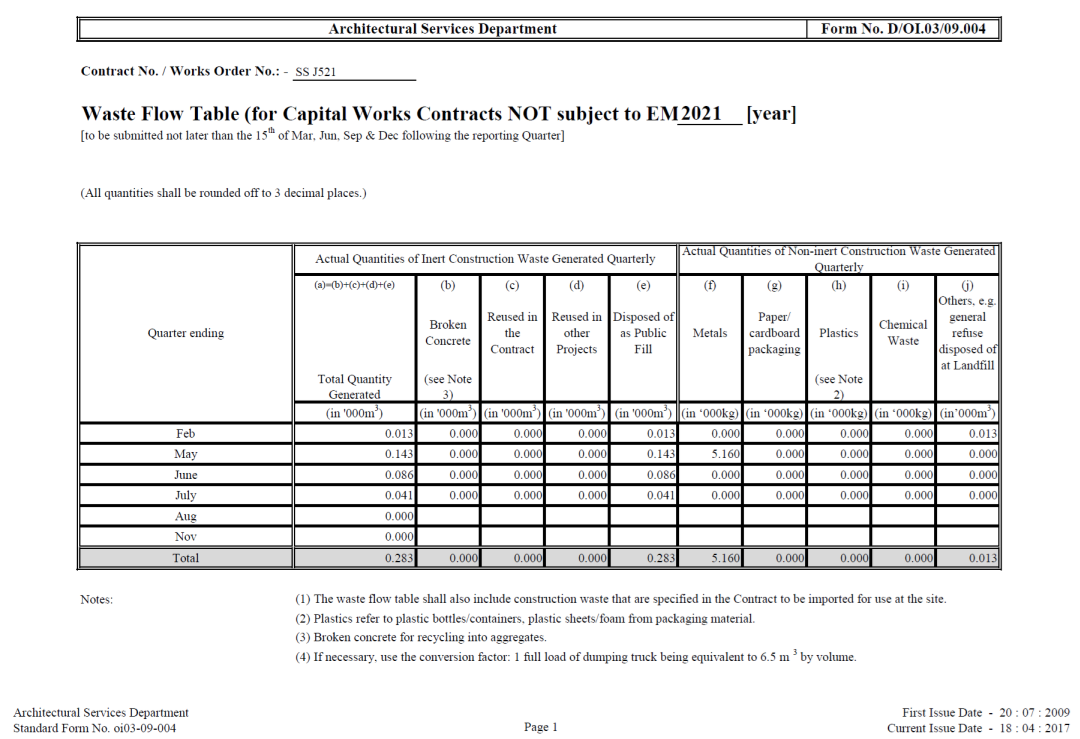

The waste generated from this Project includes inert construction and demolition (C&D) materials, and non-inert C&D materials. Non-inert C&D materials are made up of general refuse, vegetative wastes and recyclable wastes such as plastics and paper/cardboard packaging waste. Steel materials generated from the project are also grouped into non-inert C&D materials as the materials were not disposed of with other inert C&D materials. With reference to relevant handling records and trip tickets of this Project, the quantities of different types of waste generated in the reporting month are presented in Table 5.1.

Table 5.1 Quantities of Waste Generated from the Project during 2021

Five (5) sessions of noise monitoring was carried out at the monitoring locations sited at LYM in the reporting month.

No noise-related exceedance was recorded in the reporting period.

No notification of summons and prosecution was received in the reporting period.

Statistics on complaints and regulatory

compliance are summarized in Appendix H.

Site inspections were carried out on a weekly basis to monitor the implementation of proper environmental pollution control and mitigation measures under the Contract. In the reporting period, site inspections were carried out on 6, 8, 15, 22 and 29 July 2021. A joint site inspection with IEC was carried out on 6 July 2021.

Environmental deficiencies were observed during weekly site inspection. Key observations during the site inspections and during the reporting period are summarized in Table 7.1.

Table 7.1 Site Observations

|

Date |

Environmental Observations |

Follow-up Status |

|

6 July 2021 |

1. Lubricants and oil were not placed on the drip tray. The contractor should place them properly. 2. Noise barriers were not found around the power generator at Landing Facility. |

1. Lubricants and oil were removed to a proper place. 2. Erection of noise barrier around the power generator at Landing Facility. |

|

8 July 2021 |

No environmental deficiency observed. |

NA |

|

15 July 2021 |

No environmental deficiency observed. |

NA |

|

22 July 2021 |

1. At Landing Facility, chemical waste should be placed at chemical waste cabinet. 2. At Landing Facility, sump pit was overflowed, measure for site runoff control should be well implemented. |

1. Chemical Waste is removed and placed properly 2. Water at sump pit was pumped into wastewater collection tank. |

|

29 July 2021 |

1. Muddy water and refuse were observed both inside and outside the silt curtain at Landing area and existing lookout point 1. Water mitigation measures have to be enforced. 2. Only chemical waste should be placed in chemical waste cabinet. Other equipment should be removed. 3. Rust water was observed at waste storage area of Landing area. 4. A drip tray should be placed under chemical container at Landing area. |

1. Land-based control measures for muddy water generated from flushing of pipe piles at lookout point is being implemented, such as pumping muddy water to temporary tanks for storage, sedimentation and re-cycling. Meanwhile, two layers of existing silt curtain will be maintained as secondary mitigation measures. On the other hand, temporary tank for storage & sedimentation of muddy water, wetsep for further treatment at landing facility is being used during piling works. Existing silt curtain will be kept in use with close monitoring. 2. Other equipment is removed from chemical waste cabinet accordingly. 3. Rust water was cleaned from waste storage area at Landing Facility. 4. A drip tray was placed under chemical container at Landing Facility. |

According to the EIA Study Report,

Environmental Permit, contract documents and EM&A Manual, the mitigation

measures detailed in the documents should be implemented as much as practical

during the reporting period. An updated Implementation Status of Environmental

Mitigation Measures (EMIS) is provided in Appendix

B.

Works to be undertaken in the next reporting month are:

|

Works Description |

Location |

|

- 273mm Dia. pipe

piling works at lookout point |

Lookout Point |

|

Installation of steel casing for pre-bored H piles at A1 & A2 |

Landing Facility |

|

Infill Grouting of Pipe Piles |

Lookout Ponit |

|

Construction of Skin Wall and R.C Paving |

Lookout Point |

|

Dredging |

Portion A & D |

|

Stone surface truing |

Viewing Platform (left-side) |

|

Formwork / Rebar fixing |

Viewing Platform (right-side) |

|

Binding layer |

Viewing Platform (left-side) |

The major environmental impacts brought by the above construction works will include:

· Construction dust and noise generation from excavation and construction works

· Waste generation from construction activities

· Impact on water quality from marine construction works and inland construction works

The key environmental mitigation measures for the Project in the coming reporting period associated with the above construction works will include:

· Dust suppression by regular wetting and water spraying for construction works

· Reduction of noise from equipment and machinery on-site

· Sorting and storage of general refuse and construction waste

· The dredging rate shall not exceed 100 m3 per hour with a maximum working period of 12 hours per day throughout the construction phase and operation phase.

· Silt curtains should be deployed enclosing the dredging operation. Regular inspection on the silt curtain on the silt curtain condition by the contractor should be carried out.

Referring to EM&A Manual Section 4.6.1.1, the impact noise and water quality monitoring should be carried out at all the designated monitoring stations when there are project-related construction activities undertaken within a radius of 300m from the monitoring stations.

This is the 3rd Monthly EM&A Report for the Project which summarizes the key findings of the EM&A programme during the reporting period from 1 July to 31 July 2021, in accordance with the EM&A Manual and the requirement under EP-564/2018.

Five (5) sessions of noise monitoring were carried out at the monitoring locations sited at LYM in the reporting month

No water quality monitoring was conducted in the reporting period due to no marine-based works was conducted.

No exceedance of Action or Limit Level was recorded.

Weekly environmental site inspection was conducted during the reporting period. No major deficiency was observed during site inspection. The environmental performance of the project was therefore considered satisfactory.

No environmental complaint was received in the reporting period.

No notification of summons or prosecution was received since commencement of the Contract.

Agreed with the EIA prediction in Section 14.2.4.4, with the adoption of good site practice, quiet PME and noise barriers/enclosure, the noise levels at all the representative NSRs complied with the EIAO-TM noise criteria. The comparison between the EM&A data in the reporting month and the most updated noise level prediction as presented in the Noise Mitigation Plan (NMP) is presented in Table 9.1.

Table 9.1 Comparison between the EM&A Data in the Reporting Month and the Updated Noise Level Predictions

|

EIA Noise Assessment Point (NAP) |

Prediction [dB(A)] |

EM&A Monitoring Station |

Noise Levels [db(A)] |

|

HPRC V1 |

62-72 |

NM1 |

59.0 – 71.1 |

|

HPRE 75B* |

55-75 |

NM2-A |

60.2 – 62.1 |

|

LYMP |

70 |

NM3 |

66.2 – 69.1# |

|

HPRE 21C |

67-75 |

NM4 |

63.7 – 64.5 |

*NM2-A is located between NAPs HPRE 75B and HPRE 81, with lack of data in the NMP, the EIA prediction was used instead

# The noise monitoring result carried out at NM3 on 7 July 2021 was higher than the daytime construction criterion. However, this result is not considered as an exceedance as it is below the limit level after deducting the baseline noise level.

The ET will keep track on the construction works to confirm compliance of environmental requirements and the proper implementation of all necessary mitigation measures.